The relative molecular weight of the polymer has a very important influence on the dispersibility of cement. Because polycarboxylate superplasticizers are anionic surfactants and contain a large number of carboxyl hydrophilic groups, if the relative molecular weight is too large, the polymer dispersibility will be poor. If the relative molecular weight is too small, the ability of the polymer to maintain slump is not high. When the relative molecular weight is too large, it is not only easy to cause coagulation, which leads to the increase of the viscosity of the cement paste, but also shields the functional groups on the main chain that play a role in reducing water, such as carboxyl groups, sulfonic acid groups, etc., resulting in a decrease in the dispersibility of cement.

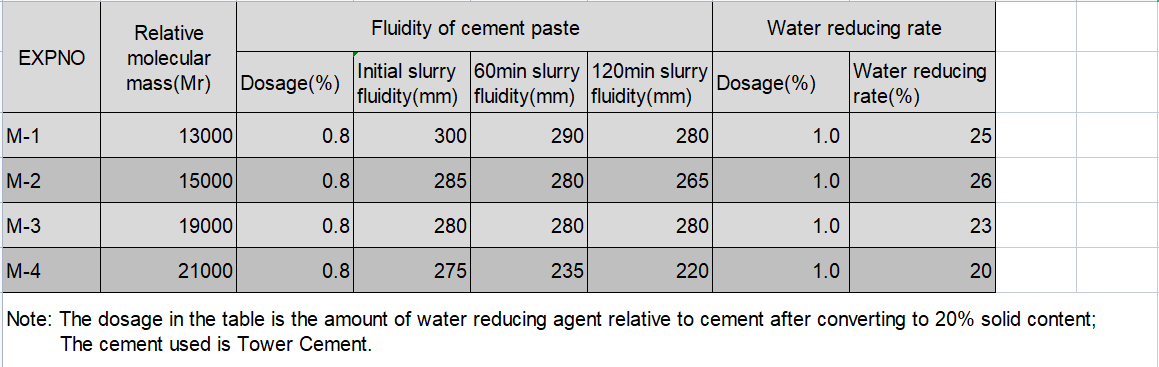

Through experiments, it is believed that the water reducing rate of the polymer first increases with the increase of the relative molecular weight, and then decreases after reaching a certain value. In this experiment, the same polymerization method and the same raw materials were used, the dosage of the regulator was controlled, and polycarboxylate water reducing agents with different molecular weights were prepared, According to GB/T 8077-2000 to investigate the influence of different molecular weights on the application performance of the product. As shown below

As shown in the figure above, the fluidity of the cement paste with smaller molecular weight increases, indicating that the low molecular weight has good dispersibility. In between 13000 and 19000 of molecular weight, the initial slurry fluidity and the fluidity with time decrease little, but when the molecular weight increases to 21,000, the fluidity loss of the slurry increases with time. This shows that the dispersibility of the cement paste by the polycarboxylate superplasticizer decreases with the increase of the molecular weight. Judging from the water reducing rate data, when the molecular weight of the polycarboxylate superplasticizer is between 13,000 and 15,000, the water-reducing rate of the water-reducing agent is not much different. When the molecular weight is above 19,000, the water-reducing rate has an obvious downward trend . It can be seen that the polycarboxylic acid mother liquor with molecular weight controlled below 15,000 has good dispersibility, high water reduction rate and small loss over time.

Post time: Nov-18-2022